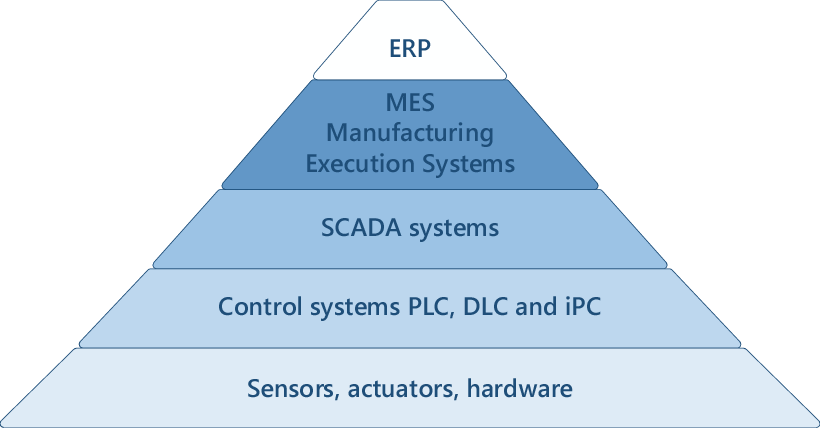

A modern industrial system is a multilevel and multicomponent network with a large number of production units and software systems interconnected through physical and logical links.

Today, manufacturers are forced to fast-adapt industrial systems to various standards and platforms in order to meet clients’ need for customized products.

Such configuration and parameterization become a very complex process due to the flexibility and openness of modern industrial systems. It is required to ensure that the settings of different components are consistent at each level, including control protocols, address spaces, and emergency actions. It is also important to ensure that intra-system interactions at different levels make it possible to integrate the system into the overall enterprise infrastructure.

All this makes the configuration process extremely resource-intensive and almost unrealizable without specialized configuration and parameterization software tools.

Such tools can automate the configuration process completely, or significantly simplify it by providing a user-friendly and intuitive user interface.

A proper configuration and parameterization tool that is based on the general system model can generate required settings, describe appropriate operating procedures, help to detect errors and offer recommendations for problem-solving.