Customer

Our customer, a medical equipment maintenance company, plays a vital role in providing essential medical gases for patient ventilation and various clinical applications in public hospitals. These gases include oxygen for life support, compressed air for surgical equipment, nitrous oxide for anesthesia, carbon dioxide for surgery insufflation, and vacuum for suction equipment.

Challenge

The medical gas pipeline system is a critical component in every hospital, requiring compliance with regulatory standards and optimal efficiency for patient safety. Some gases are classified as pharmaceuticals, demanding adherence to strict regulatory standards.

To ensure comprehensive service, reduce maintenance costs, and avoid time-consuming visual inspections, the customer sought to build a monitoring system for medical gas pipeline equipment.

Solution

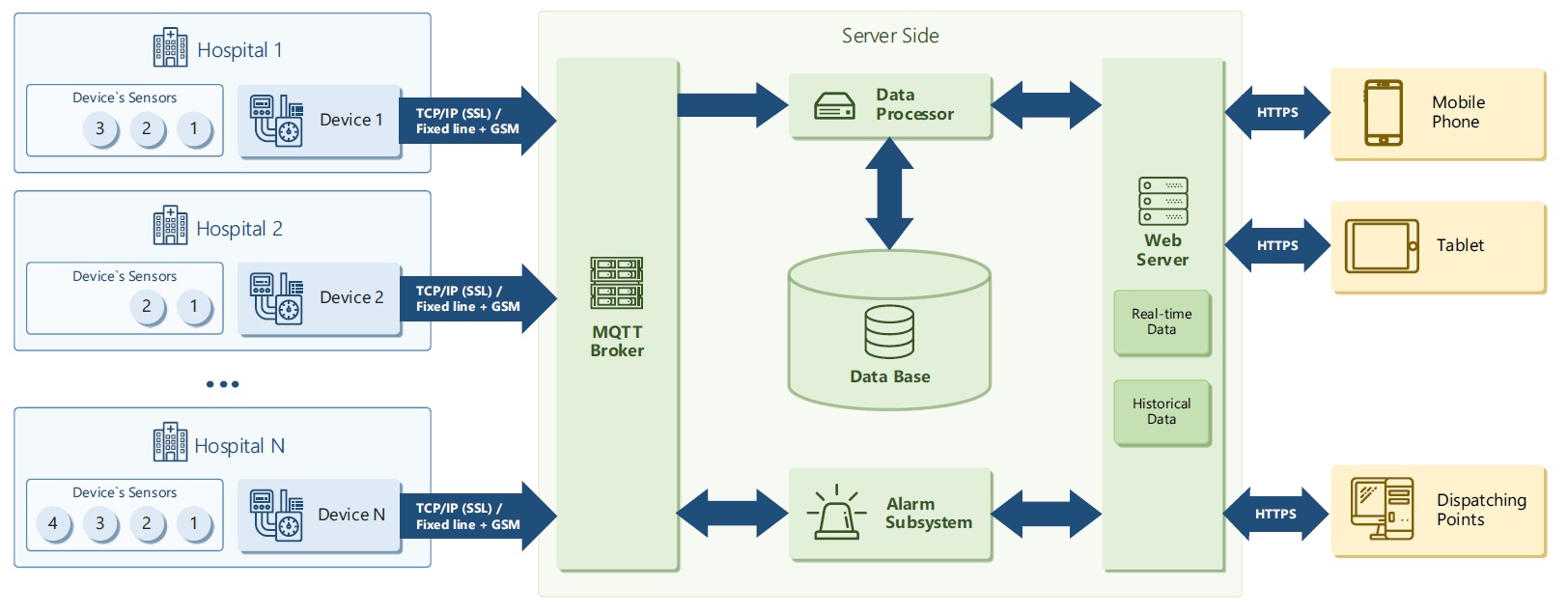

We designed an IoT system architecture based on open-source instruments for data acquisition, storage, and visualization, completing the implementation in approximately 2 months.

The system includes back-end, front-end, and embedded software for edge devices, allowing data collection and display from up to 500 controllers with a frequency of 10-100 Hz.

System operators and repair teams can connect to the system via PC or mobile phone using fixed line and GSM channels for communication reliability.

Our IoT solution ensures a secure connection of gas monitor devices to central supervision system, which enables collection of all data (including alarm messages) from medical gas pipeline equipment and distribution of this information to the relevant specialists and organizations.

System capabilities:

• Real-time data collection and display with specified frequency;

• Web interface with multilevel location objects on the map;

• System filters for easy navigation;

• Scalability with MQTT protocol for adding new devices;

• Configurable alarm subsystem for device and sensor thresholds;

• Data storage in the database for future analysis;

• Chart and report generation based on historical data.

Technology Stack:

• Web server: GO, HTML5, CSS, JQuery, Infragistics;

• M2M protocol: MQTT, Mosquitto broker;

• Database: MongoDB;

• Device: Implemented MQTT protocol (STM32 microcontroller);

• Security: openSSL, PolarSSL.

Results

Our IoT solution empowers the customer to monitor the status of medical gas supply systems across a network of public hospitals, enabling punctual and cost-effective maintenance and repair.

Key features:

• Geographically distributed devices;

• Lightweight M2M protocol for data collection;

• Security protocols for transmission channel protection;

• Real-time data storage for future analysis;

• Web interface for displaying real-time data;

• Configurable alarm subsystem;

• GSM 3G and SMS service;

• Built using open-source instruments.

This innovative IoT-based medical gas monitoring system enhances efficiency, reduces costs, and ensures the reliability of medical gas pipeline equipment, contributing to improved patient care in public hospitals.