Customer

The customer is a prominent player in the automotive industry, renowned for providing innovative hardware and software solutions for vehicle emission testing. With a global presence spanning 45 countries and a dedicated team exceeding 10,000 professionals, our customer prioritizes technical excellence, usability, and customization in their product offerings.

Challenge

In line with our customer's commitment to innovation and user-centric design, Applied Systems undertook the challenge of developing a modern multilevel HMI (Human-Machine Interface) system. The primary objectives were to ensure interactive control of complex equipment, enhance overall usability, and provide a high degree of customization to adapt to diverse end-user equipment options.

Solution

Applied Systems engaged in a meticulous process of gathering and analyzing customer requirements, aiming to preserve the best features of existing systems while supporting the new generation of equipment. Collaborating closely with engineers and experts, we initiated the development process based on comprehensive specifications.

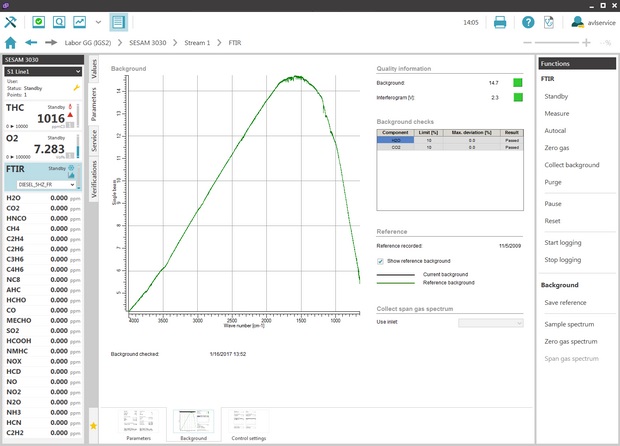

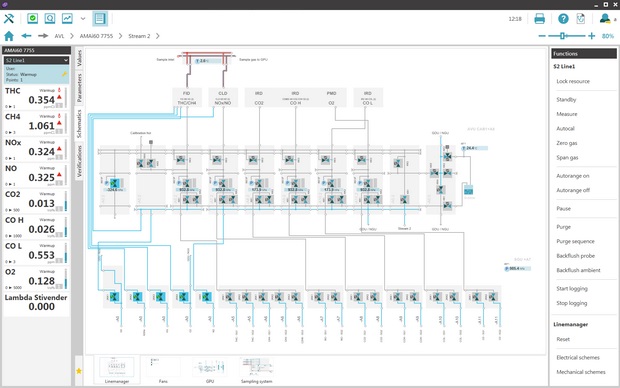

One of the key innovations was the implementation of automatically generated gas-flow diagrams. UI (user interface) panels represent dynamic schemes of the controlled equipment (e.g. valves or pumps.) with "live" control elements, reflecting the current state of gas flows and equipment and allowing to change this state by several clicks.

Key features of the customizable HMI:

• User dashboards for centralized information;

• Intuitive navigation across different interface levels;

• Vivid representation of component parameters;

• Special controls for flexible usage;

• Creation of compound data-from-time and data-from-data graphs;

• Implementation of automatically generated gas-flow diagrams;

• UI panels with dynamic schemes reflecting real-time equipment status.

Results

Results

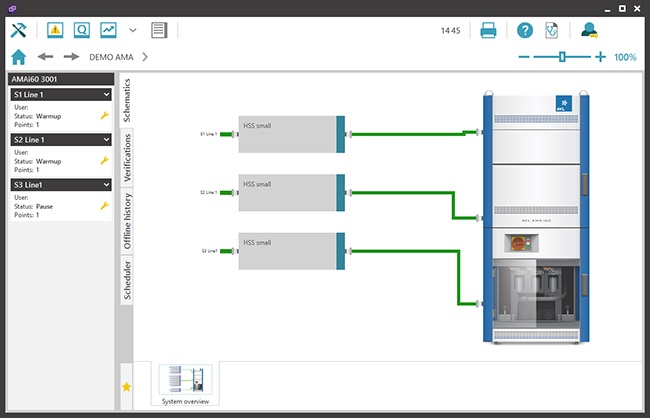

Our development team successfully delivered a customizable three-level HMI system, catering to varying degrees of refinement:

- Upper Level (System Level): Represents the basic view of controlled equipment (e.g., benches).

- Subsystem Level: Represents subsystems, such as gas streams, each with a set of involved UI panels.

- Detailed Level (Device Level): Provides individual UI panels for each device or unit.

The three-level HMI offers a comprehensive system overview and easy access to specific details within 2-3 clicks. Positive market feedback led to the seamless integration of our HMI components into a series of customer products.

Applied Systems' commitment to creating a customizable and user-friendly HMI system has resulted in a powerful tool for emission measurement applications, meeting the high standards set by our esteemed customer in the automotive industry.