Customer

Our client, a prominent German company specializing in device integration and management software development, holds a leading market position in providing reliable communication solutions to clients in the process industries. Their clientele includes instrumentation and control systems vendors, as well as plant operators.

Challenge

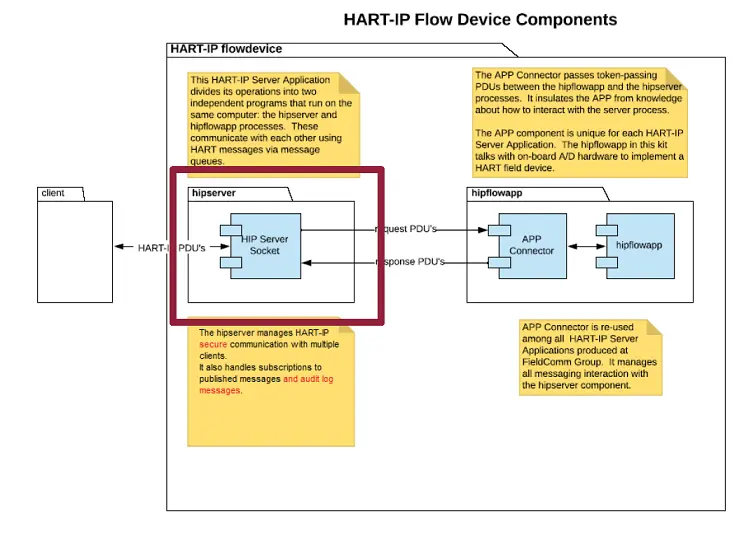

HART-IP, known for its simplicity and high-level application protocol, offers an efficient means to access information from HART-enabled field devices within existing network infrastructures. The challenge was to update the Linux-based HART-IP server to incorporate specific features requested by the client. These features included support for TCP communication with SSL/TLS based on the OpenSSL library, direct messaging between clients and field devices, publishing events on a remote server, and support for resetting to hardware factory settings while the HART-IP server is running.

Solution

Our team embarked on a comprehensive solution development process, encompassing the creation of a complete environment with missing components replaced by stubs.

The development proceeded through three stages, with each stage delivering components and a 'green' list of automated tests, updated to incorporate the latest implemented features. Customer specialists verified the code, compiled, and ran tests on their end after each stage.

Key implemented tasks included:

• Refactoring the HART-IP communication part to support TCP protocol alongside UDP;

• Implementation of DirectMessage PDU in parallel with Token-Passing Data-Link Layer PDU for enabling direct communication between clients and field devices;

• Event logging into the system log;

• Secure login to a remote server log;

• Support for secure SSL/TLS communication via TCP/UDP;

• Provision of interfaces for HART-IP server configuration, allowing changes to host and ports;

• Support for resetting to hardware factory settings while the HART-IP server is running.

Results

Our efforts resulted in delivering an updated HART-IP server functionality, along with a test client equipped with automated tests. The developed solution facilitates secure remote access to manage HART-enabled field devices for multiple clients simultaneously, addressing the evolving needs of industrial process automation and production system automation.