Customer

Profile Our client, a prominent Austrian-based provider of integrated hardware and software solutions for vehicle emission testing in the automotive industry, boasts a global presence with over 10,000 employees and operations spanning 45 countries.

Challenge

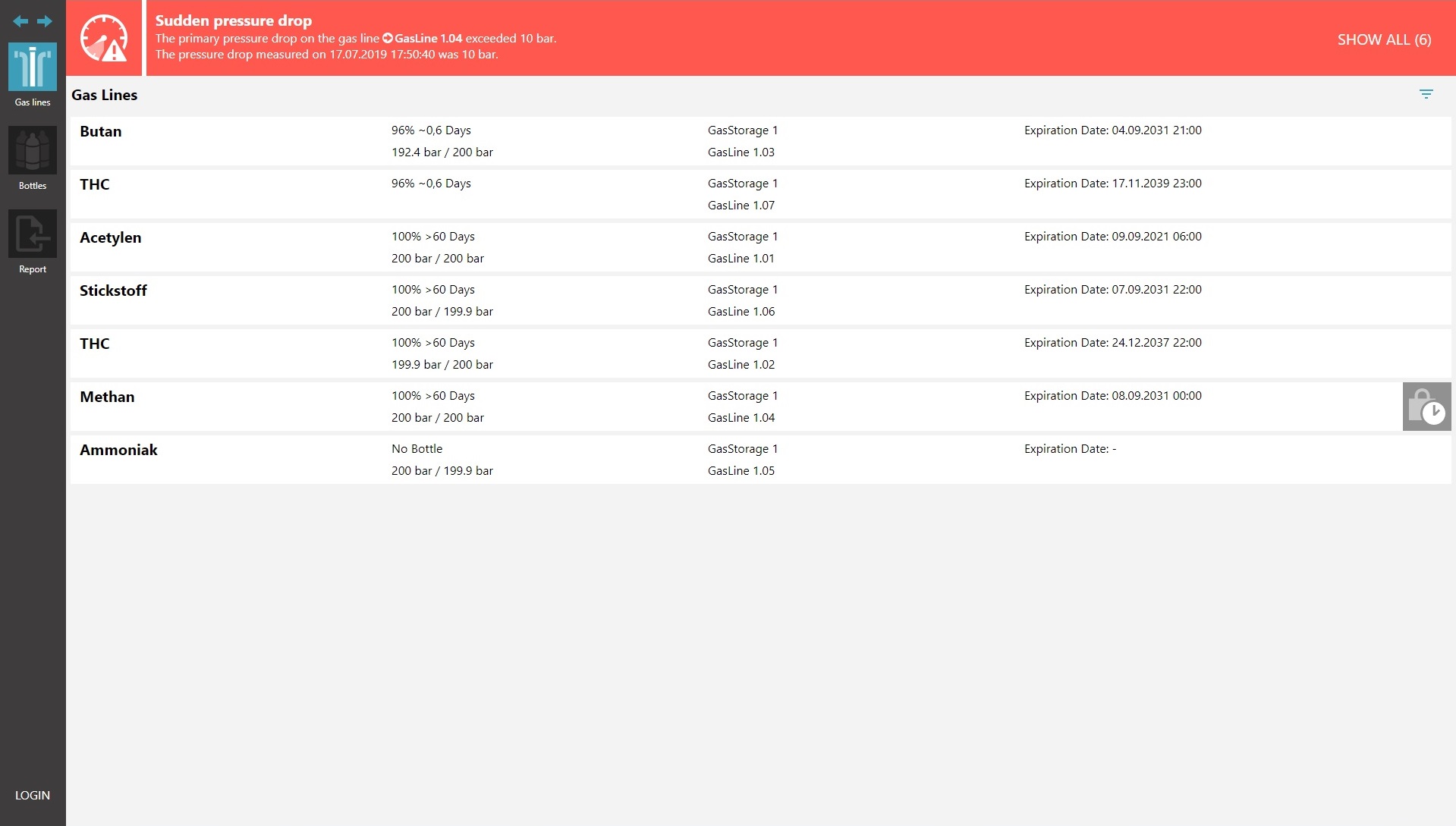

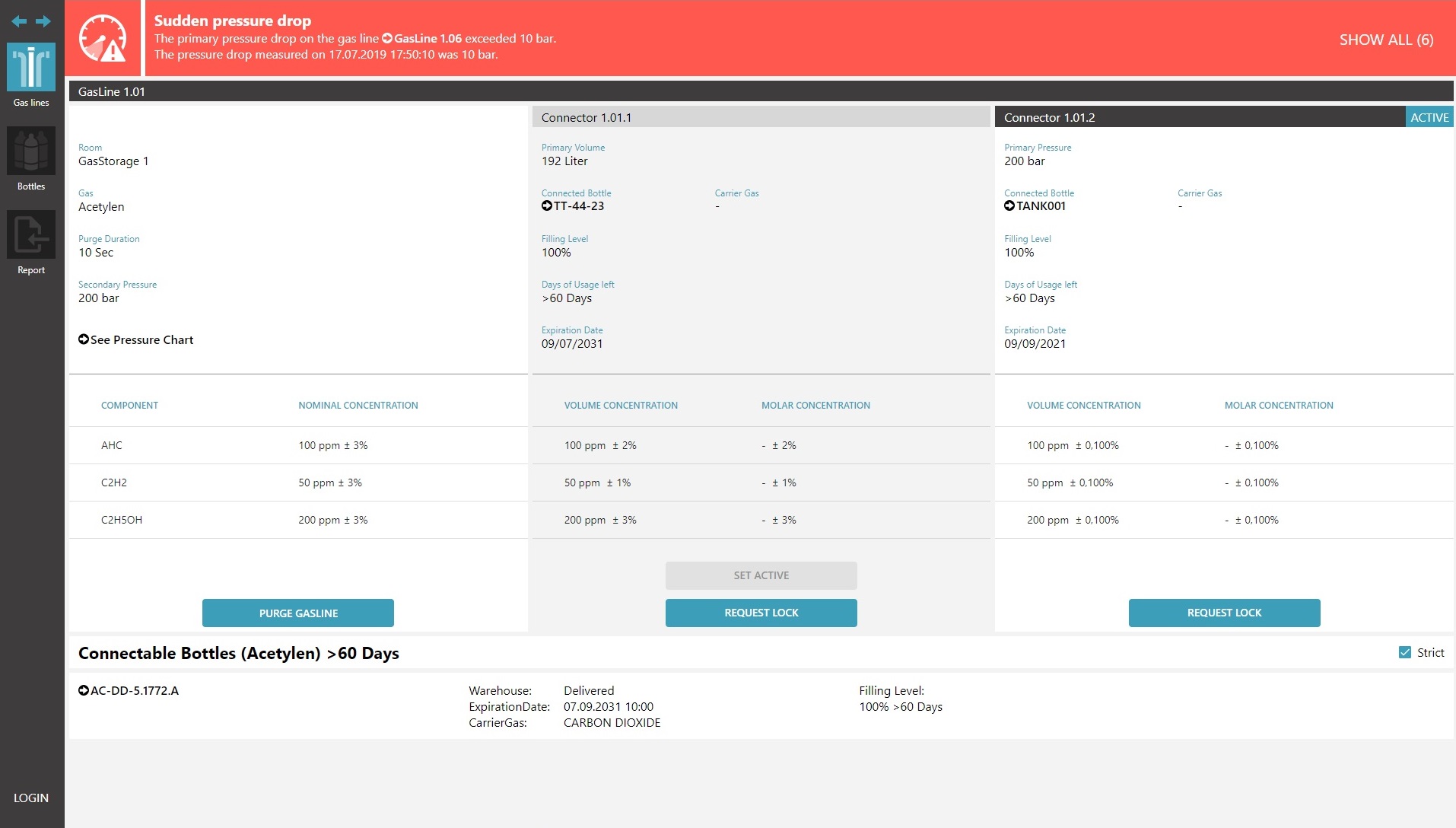

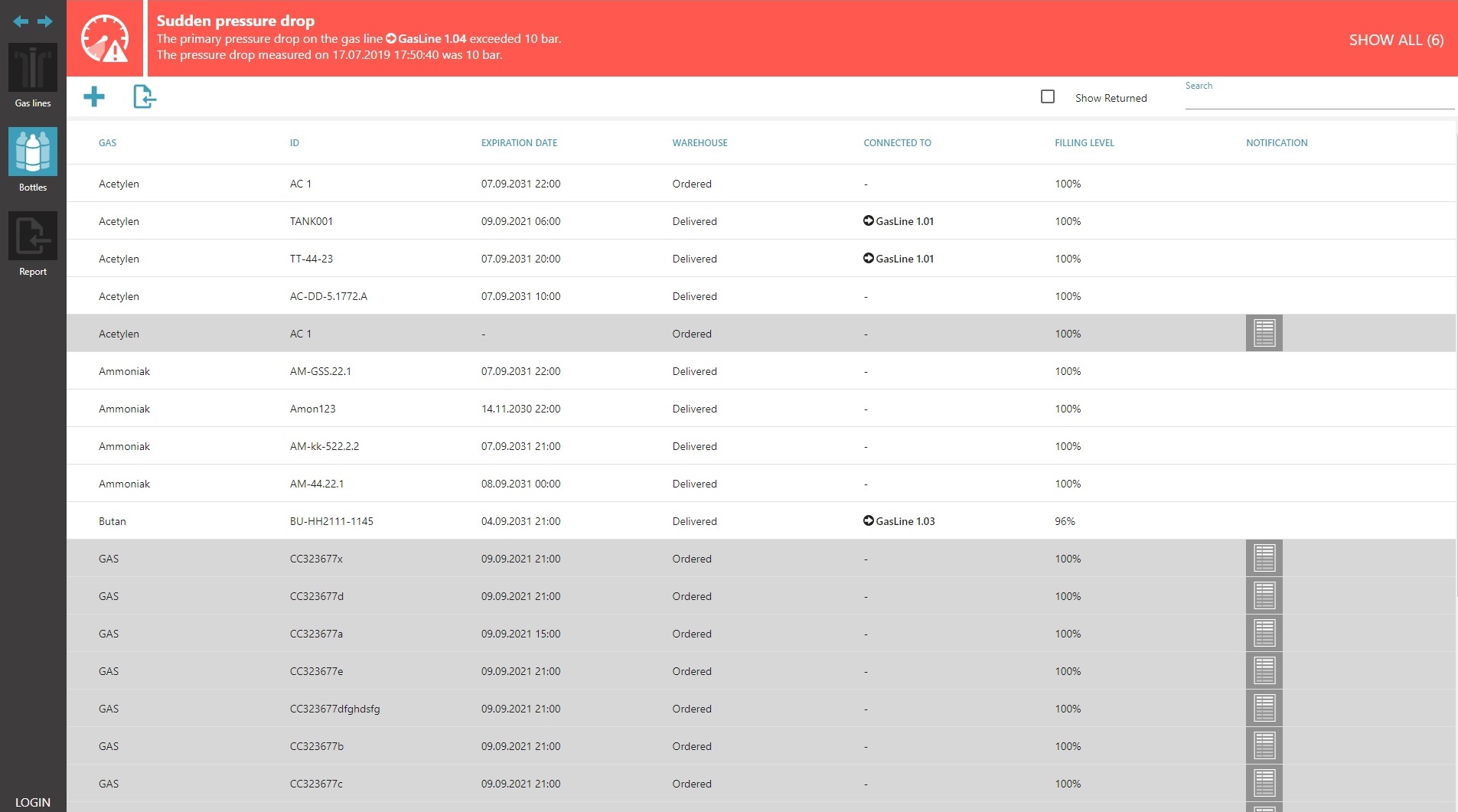

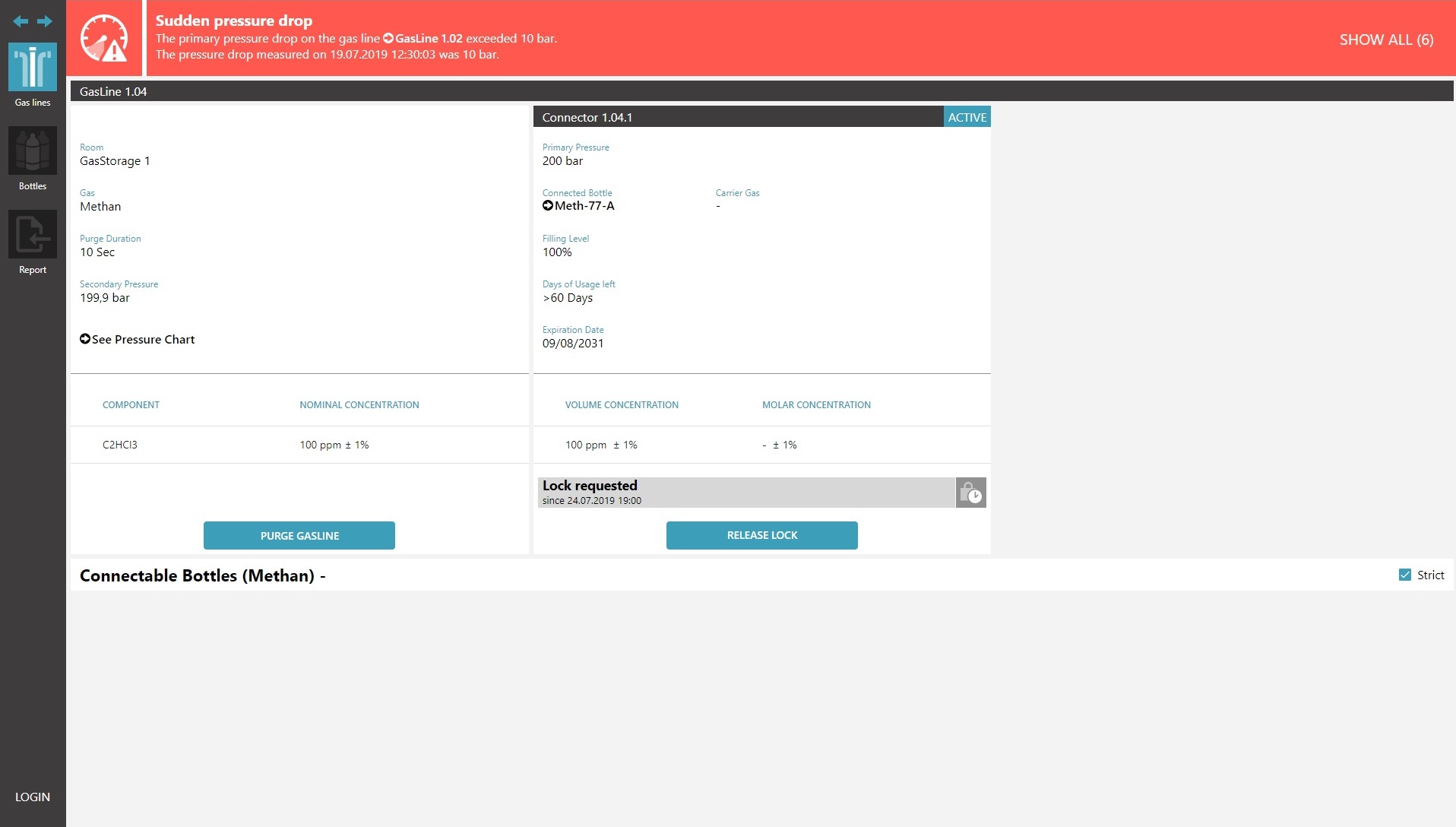

Our client is deeply involved in emissions testing across various powertrain systems, necessitating the use of diverse gases for calibration purposes in compliance with legal emission testing protocols. These gases are stored in cylinders within dedicated storage facilities. Each gas cylinder is equipped with a pressure sensor connected to a measuring device.

The monitoring system's primary goal is to oversee the condition of gas supply equipment, cylinder integrity, leak prevention, and quality maintenance. In response to operational challenges, our client sought to develop an updated gas management system. The aim was to optimize maintenance costs by reducing the need for operational personnel and minimizing gas wastage while transitioning the system from a desktop solution to a web-based environment.

Solution

We devised a comprehensive, centralized solution encompassing servers, client-server applications, and user-friendly graphical interfaces. Our system allows operators to monitor the gas supply infrastructure from both desktop platforms (Windows 7, 10; Google Chrome) and mobile devices such as smartphones and tablets (Android, iOS). The intuitive graphical user interface empowers personnel to swiftly address emergencies and efficiently manage a multitude of critical indicators.

Key System Features:

• Real-time monitoring of gas bottle pressure and fill levels for various calibration gases.

• Tracking of gas cylinder expiration dates and estimated operational durations.

• Customizable notification settings for pressure deviations, expiration dates, and remaining gas volume.

• Automatic transmission of warning notifications when tracked indicators deviate from established thresholds.

• Automated gas line purging.

• Gas bottle locking and unlocking mechanisms.

• Seamless registration of new gas bottles in the system by scanning QR codes or PDF files from gas cylinder manufacturers.

• On-demand generation of system status reports.

Results

Our solution was seamlessly integrated into our client's automotive engine testing workflow, resulting in optimized system maintenance costs and expedited regulatory documentation completion. The gas management system effectively maximizes the number of valid tests through its gas bottle locking feature and automated gas line purging, enhancing the efficiency of the testing process.