Customer

Our valued client, a reputable German company and an active member of FieldComm Group, frequently participates in the development of tools and common components for Field Device Integration (FDI) standard implementations.

FieldComm Group, a global non-profit organization, collaborates with leading manufacturers, universities, and research institutions to establish communication standards for the process industries.

The FDI standard, jointly developed by prominent process industry foundations including FieldComm Group, PROFIBUS International, and the OPC Foundation, promotes seamless interoperability among diverse field device suppliers and software vendors. This technology streamlines software installation, configuration, maintenance, and field device and host system management.

Challenge

Our client faced the task of incorporating a set of new requirements for the upcoming release of FDI Host common components. To meet this goal within the stipulated timeline, they opted to expand their team and enlisted Applied Systems as their trusted software development partner. In a matter of months, our team had to:

• Gain a comprehensive understanding of the FDI standard.

• Familiarize themselves with the existing codebase of the FDI Common Host components package.

• Implement the requested enhancements.

• Develop automated tests for the implemented functionality.

Solution

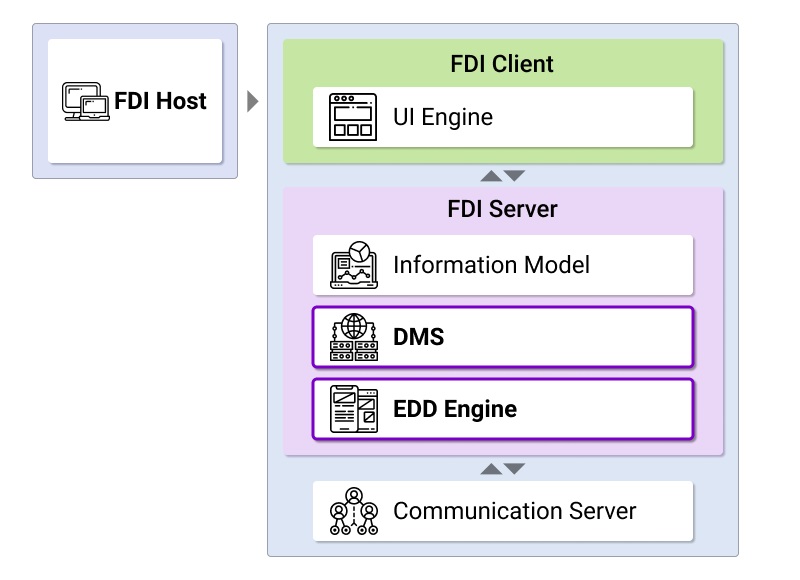

The implementation of the requested changes necessitated interaction with two FDI Host Common components:

• EDD engine, the interpreter for EDD (electronic device description) language.

• Device Model Services (DMS), responsible for constructing an information model based on data extracted from EDD files and providing it to other system components.

The scope of work encompassed:

• Expanding support for EDD language with semantic maps in the DMS component.

• A comprehensive list of bug fixes and improvements for the DMS implementation.

An integral aspect of development was ensuring that these changes didn't impact existing functionality. Given that FDI Host common components are widely utilized by FieldComm Group members, the risk of functional alterations had to be minimized. Hence, the entire codebase underwent extensive automatic testing. This testing routine was extended to cover each feature, improvement, and update across all modules.

Right from the outset, our client and Applied Systems engineers worked closely together, benefiting from their extensive experience in industrial software development. An agile development process was established, featuring daily meetings, peer reviews, and regular demo sessions.

The development process was divided into two iterations, with a complete functional update delivered to the customer after each iteration.

Results

Leveraging their substantial experience in industrial IT, the Applied Systems team adeptly addressed this complex technological challenge. They successfully implemented all specified requirements within the defined timeline and budget.

Our team has made a significant contribution to the evolution of FDI technology while preserving existing functionality and upholding the high-quality standards characteristic of the FDI development community.