Customer

Our esteemed client is a prominent industry leader specializing in the development of equipment and software dedicated to monitoring the safety of industrial systems.

Challenge

As a manufacturer of safety PLCs crucial for safeguarding industrial equipment, the customer encountered complexities when integrating new devices into control systems. Updating device information and customizing system parameters posed a challenge. The transport layer, specifically EtherCAT, required meticulous configuration to ensure optimal performance and low response time.

The customer aimed to augment the functionality of the PLC program editor, simplifying the configuration of system parameters after importing new devices. The goal was to expedite EtherCAT network setup by creating a service to import data from ESI and ENI files of connected devices for automatic system configuration.

Solution

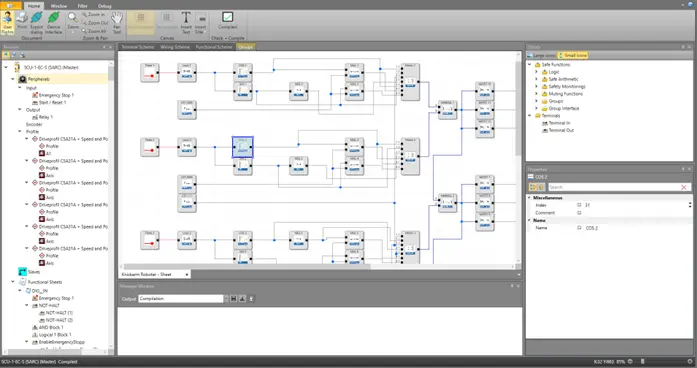

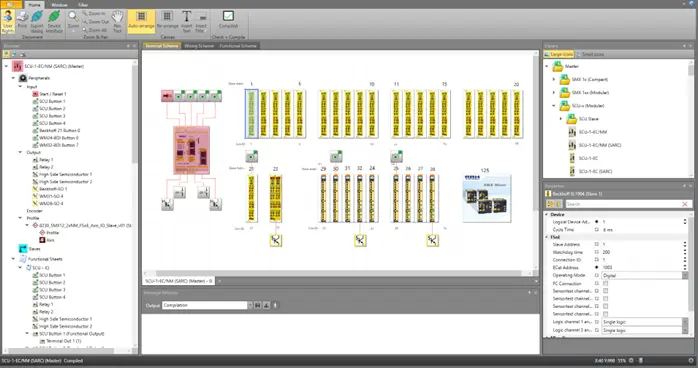

The PLC program editor, pivotal for system configuration and network communication visualization, saw the integration of the EtherCAT configurator. Our engineers seamlessly integrated this component without compromising the existing system's functionality.

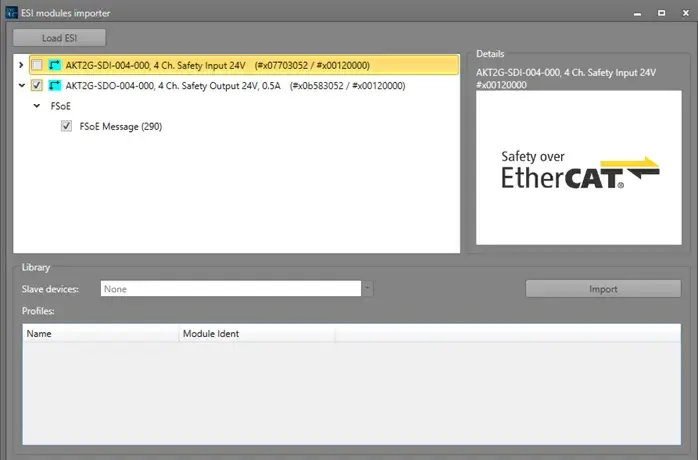

Configuration details essential for communication with a specific device are embedded in the ESI file accompanying EtherCAT protocol devices. The ESI (EtherCAT Slave Information) file, an XML document, is used to customize slaves and create the ENI (EtherCAT Network Information) file, essential for generating network topology description files.

Key features of the EtherCAT configurator include:

- Addition of new slave devices to the program editor library.

- Configuration of system parameters such as device description, data types, and settings using information from the loaded ESI file.

- Visualization of necessary information from the ESI file in the GUI, allowing the system operator to select required packages and load specific modules.

- Automatic customization of parameters required for integrating new modules into the system after loading into the program editor.

Additionally, the EtherCAT configurator facilitates working with ENI files, describing network topology and visualizing the current system configuration based on the information contained in the ENI file.

Results

The successful integration of the EtherCAT configurator into the PLC program editor enabled the customer to simplify the process of importing new EtherCAT-connected devices. This enhancement streamlined customization, reducing the likelihood of human errors and significantly speeding up the overall process of system configuration.