Customer

The customer develops and tests powertrain systems. One of the key areas of expertise is emissions testing for the certification of engines and vehicles in compliance with the emission legislations. Gases sampled from the exhaust system must be diluted with air in a strictly defined proportion and homogeneously mixed before testing to ensure the accuracy of measurements.

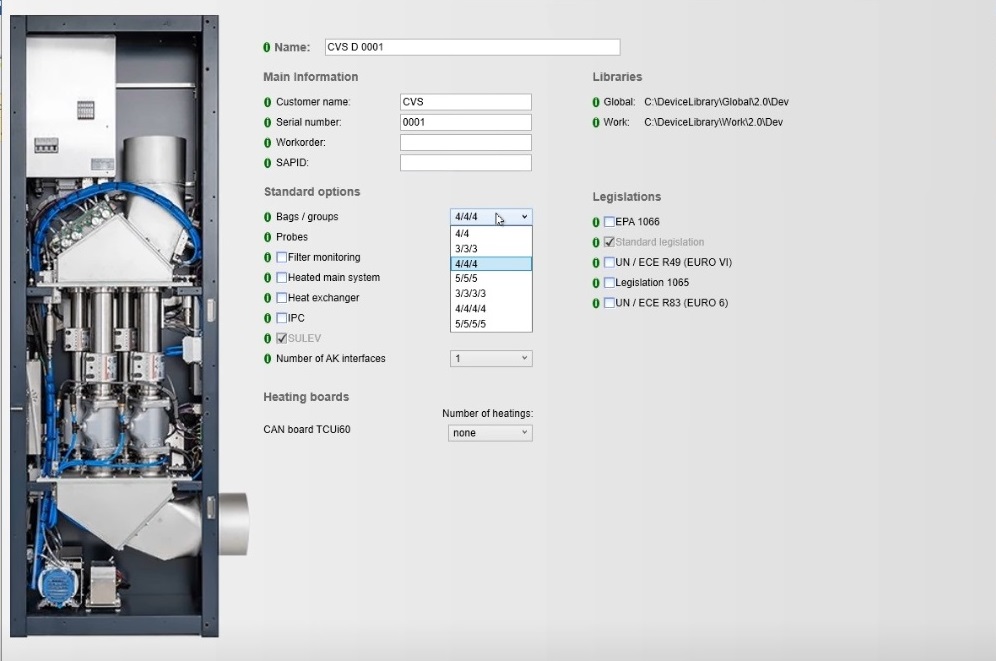

The constant volume sampling (CVS) system is designed to dilute the full volume of emission gases with air and to sample a part of the gases into bags. The system consists of many components: venturis, groups of bags, heat exchangers, flaps, sensors, etc.

Challenge

The system parameterization is a complex process due to a large number of customizable options since different contractors order various configurations of the CVS system for their test cells.

The customer needed to upgrade the configuration software of the CVS system to be able to operate on new test equipment and comply with the latest emission regulations. One of the important requirements was to ensure parameterization according to customer standards with maximum reuse of software components and system logic from previous versions of the system.

Solution

We have carefully analyzed customer requirements for configuration software, learned all the parameters of the CVS system, both for hardware and control software.

Our engineering team also considered the experience of manual customization of such systems. The practice showed that the step of the creation of gas flow diagrams was very time consuming and error-prone.

Key functions of the configuration software solution for the CVS system:

• Customization of equipment for specific contractor request;

• Configuration of control software;

• Setup the calibration and diagnostics routine.

The configurator should provide the ability to use CVS equipment with two or more test cells.

To fully configure the system the user shall go through just a few configuration steps.

The intuitive interface allows maintenance engineers to enter essential information required for the parameterization of the constant volume sampling system.

Our solution creates a whole configuration of the CVS system. A special algorithm generates a digital signature indicating that the essential parameters are unchanged to prevent tampering.

After completing the configuration process, the self-diagnostic procedures are activated and the system is calibrated.

We have paid special attention to the development of algorithms for the automatic generation of specific gas flow diagrams.

Our specialists have created a user-friendly interface to control each element of the exhaust gas dilution system in a simple and convenient manner.

Results

Our team has created the CVS configurator that can automatically generate parameters to adjust the hardware, software components, as well as create gas flow diagrams in accordance with specified contractor requirements.

The developed instrument helps to reduce the time required for parameterization of the emission test equipment and avoid human errors.